Thin-walled ring pieces, poor rigidity, large amount of material removal, prone to deformation during processing; High dimensional accuracy, strict technical requirements; complex internal structure, narrow ring groove area, small spacef or tool; thin wall of ring groove, with uneven thickness; mostly made of high temperature alloy, usually using ceramic cutting tools and CNC milling cutte rto efficiently remove the allowance.

Usually using ceramic cutting tools and CNC milling cutter to efficiently remove the allowance

Boss surface

machining

FMA11

series economy face milling

cutter, with soft

cutting action, for high quality face milling of thin-walled boss.

Slot milling

MPHT * -

NM insert for SMP03 tool, with groove structure, fine grinding, edge sharpness treatment,

for roughing where flatness and straightness of groove bottom are not demanded.

CNE * -

NM insert for SMP12 tool, fully ground. Geometry can be designed according to

work piece material and insert nose can be customized. With excellent geometry

bottom straightness and flatness, it is suitable for finishing.

Face and

side milling cutter can be customized according to the customer’s actual

machining requirements. Variable data include interface form, cutter diameter,

cutting width, maximum cutting depth, cutting profile angle, nose radius size, etc.

Finish milling

VSM

uneven pitch milling series are mainly applied for side milling, slot milling

and profile milling in S- materials.

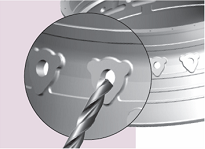

Hole making

SD series drill

Main cutting edge is

in convex curve shape, with lengthened cutting edge, reducing the load per unit

length, effectively slowing down tool wear; Negative rake angle of groove and

increased tool angle improve the heat-dissipation conditions of the nose.

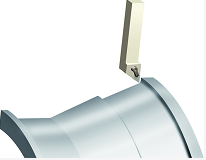

Turning

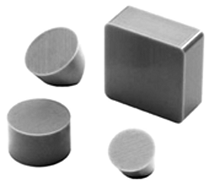

Ceramic

inserts, with excellent groove wear resistance, larger cutting depth, higher

efficiency and longer tool life.